PRODUCT CATALOG

Sugar Roller Mill Arcing Electrodes / Wire

Azucar STS 80 (LINCOLN ELECTRIC MAKE)

CLASSIFICATIONS: AWS 2576 2358-A4 | DIA 8555 E-10-55r

PACKING: 3.25 mm X 350 mm – 15 kgs sealed tin packing | 4.00 mm X 450 mm – 20 kgs sealed tin packing

Roller wear can loose 15-25% of the cane feeding rate as the sugar mill feed rolls becomes smooth and loose their grip. Azucar STS 80 increases the efficiency and the life of the mill by adding a rough wear resistant deposit of high alloy carbide type weld metal which increases traction. Surface area is increased by 12% and the co-efficient of friction by 0.4. Azucar STS 80 can be applied while the mill is running as well as on dry rolls, thus reducing non profitable down time. This will effectively increase the overall surface area of the roller by 16% resulting in maximizing the grip on cane and thereby reducing POL%, wear and stoppage and increase recovery by 0.25 to 1% maximum.

The hardness and resistance to impact make this electrode suitable for use in a large variety of applications which include mill roller roughening, excavator bucket lips and teeth, dragline buckets, conveyor screws, rock chutes etc.

To be limited to maximum two layers and has to be held at an angle of 45° to 90° from the horizontal. This has to be done when the roller is moving at 3 to 4 rpm. For simple hard facing application this has to be done on down hand position at 140 to 180 amps.

54-60 HRc

For 3.25mm X 350mm – 110 to 180Amps

For 4.00mm X 450mm – 130 to 180Amps (Dry) and 180 to 230Amps (Wet Condition) in touch with roller

Sugar Roller Mill Arcing Electrodes / Wire

Unimax V-80 (LINCOLN ELECTRIC MAKE)

CLASSIFICATIONS: AWS 2576 2358-A4 | DIA 8555 E-10-55r

PACKING: 3.25 mm X 350 mm – 15 kgs sealed tin packing | 4.00 mm X 450 mm – 20 kgs sealed tin packing

Unimax V-80 deposits a tough eutectic of austenite and metal carbide that can withstand impact at medium loads under abrasive conditions. Deposits are rough and globular protrusions of high alloy complex martensitic chromium carbides.

The hardness and resistance to impact make this electrode suitable for use in a large variety of applications which include mill roll roughening, excavator bucket lips and teeth, dragline buckets, conveyor screws, rock chutes, etc.

The application of this electrode is best limited to two layers. It should be further noted that deposits are subject to relief checking.

54-60 HRc

For 3.25mm X 350mm – 110 to 180Amps

For 4.00mm X 450mm-130 to 180Amps (Dry) and 180 to 230Amps (Wet Condition) in touch with roller

Sugar Roller Mill Arcing Electrodes / Wire

Lincoln-STS TUB 1001 M OA (LINCOLN ELECTRIC MAKE)

Metal Cored Wire designed to be used without shielding gas (open arc) developed to deposit in transfer, an alloy of Chromium Carbides in an austenitic matrix of high hardness resistant to wear by abrasion in a humid environment, providing excellent performance during sugarcane milling. This filler metal is used to coat milling jackets in the sugar- alcohol Industry by spraying, providing better bagasse drag and increased yield.

Excellent performance using a convertional torch for dry splattering (off-season) applicable on power source machine for open arc with changeable nozzle size that responds adequately to the demands of the environment of the process of spraying.

This filler metal does not require shielding gas (open arc), recommended for semi-automatic, automatic and robotic applications using a constant voltage power source (CV) direct current and reverse polarity (DCEP). The best performance is achieved using power source welding equipment.

53-60 HRc as welded

Recommended Welding Parameters

| WIRE DIAMETER (mm) | WELDING POSITION | AMPERAGE (A) | VOLTAGE (V) | CTWD (mm) |

| 2.4 | Flat and Horizontal | 200 – 400 | 27 – 36 | 25 to 35 |

| 2.8 | Flat and Horizontal | 200 – 400 | 27 – 36 | 25 to 35 |

| DIAMETERS / PACKAGE | ||

| DIAMETER | ||

| 2.4 | 12.5 kg SPOOL | 100 or 250 kg DRUM |

| 2.8 | 12.5 kg SPOOL | 100 or 250 kg DRUM |

Special Hardfacing Electrodes

Azucar STS 100 (LINCOLN ELECTRIC MAKE)

CLASSIFICATIONS: AWS 2576 2355-A4 | DIA 8555 E-10-55A

PACKING: 3.25 mm X 350 mm – 15 kgs sealed tin packing | 4.00 mm X 450 mm – 20 kgs sealed tin packing

This is a chromium carbide hardfacing electrode for use in the downhand position only. The weld deposits are unmachinable but can be ground. The deposited metal is highly resistant to abrasive wear with moderate to high impact and is recommended for special hard facing applications on carbon steels, 14% manganese steels and cast iron. Can be used for hardfacing components subject to high temperature upto 600°C.

In sugar mills Azucar STS 100 can be used for the hardfacing of cane knives fibrizor hammers shredder hammers, trash plates, scrapper plates, screw conveyor, arm grabs, excavator bucket lips and teeth and TRPF rollers. This electrode also has many applications in the Steel, Power, Cement, Paper and Mining Industries.

All the above components can be hardfaced after removing the old weld deposit if any by grinding. The welding procedure should follow from top leading to end using crisscross welding pattern with maximum two layers to eliminate relief checks.

58-64 HRc

For 3.25 mm X 350 mm – 100 to 130Amps

For 4.00 mm X 450 mm – 140 to 180Amps

Special Hardfacing Electrodes

Azucar HF 350 R

CLASSIFICATIONS: ASW 2576 1130 – A4 | DIN 8555 E-1-300

PACKING: 4.00mm X 450mm-5 kgs sealed packing

This is a basic coated all position electrode depositing a tough chromium alloy weld metal. This is capable of withstanding high impact and rolling loads with good resistance to mild abrasive and frictional loading.

Azucar HF 350R is suitable for rebuilding worn mild steel or low alloy machine parts which require machining after welding. This can also be successfully used as an underlay or buffer between base material and harder overlays (with Azucar STS 100). Typical components to be welded with this electrode include shafts, mine car wheels, mill pinion, track links, dragline chains, tractor rails, drive sprockets etc.

This electrode is suitable for positional welding and can be multilayered. (Max 4 layers). This can also be hardened to above 480 HV by heating to 900°C and quenching in oil. for mill pinion hard facing old fatigued material have to be removed by grinding before depositing Azucar HF350 R.

26-31 HRc

4.00 mm X 350 mm-140 to 180 Amps

Polarity DC +AC 70 OCV min

Special Hardfacing Electrodes

Azucar HF 650 R

CLASSIFICATIONS: DIN 8555 E6-UM-606

PACKING: 4.00mm X 450mm-5 kgs sealed packing

This electrode has very good abrasion resistant properties. This deposits weld metal containing chromium, molybdenum and vanadium and is grindable. Because of its high alloy content, the deposited weld metal has excellent hardness.

Azucar-HF650-R deposits martensitic (a formation of chromium carbide) steel weld metal which is suitable for use on a wide variety of tool and metal-to-metal applications such as guillotine blades, punches, dies, pneumatic drills, chisels, axes, ripper teeth, wood chipper anvils, Cane Cutting Knives, Trash plates, Scrapper plates (Point and side portions) Arm Grabs, Kickers, ID Fan Blades hammer etc.

This electrode is suitable for positional welding and may be multilayered. (Max 4 layers). This should be re-dried at 350° C for two hours prior to use for maximum efficiency.

57-62 HRc (3 layers)

4.00 mm X 350 mm-120 to 160 Amps

Polarity DC+AC 70 OCV

Special SS Electrode

Azucar SS 309L

CLASSIFICATIONS: AWS A5.4 E309L-16 | ISO 3581 E23.12 LR26 | DIN 8556 E23 12 LR26

PACKING: 4.00mm X 350mm – 4 kgs sealed packing | 4.00 mm X 450 mm 5 kgs plastic box

HARDNESS: 54-60 HRc

This is a rutile basic extra low carbon grade electrode used in SS and welding repairs of any type of alloy steel components like shafts, impellers and heat resistant steel. This is resistant to any type of corrosion and has 22 to 25% chromium and 12% nickel. Its machinable.

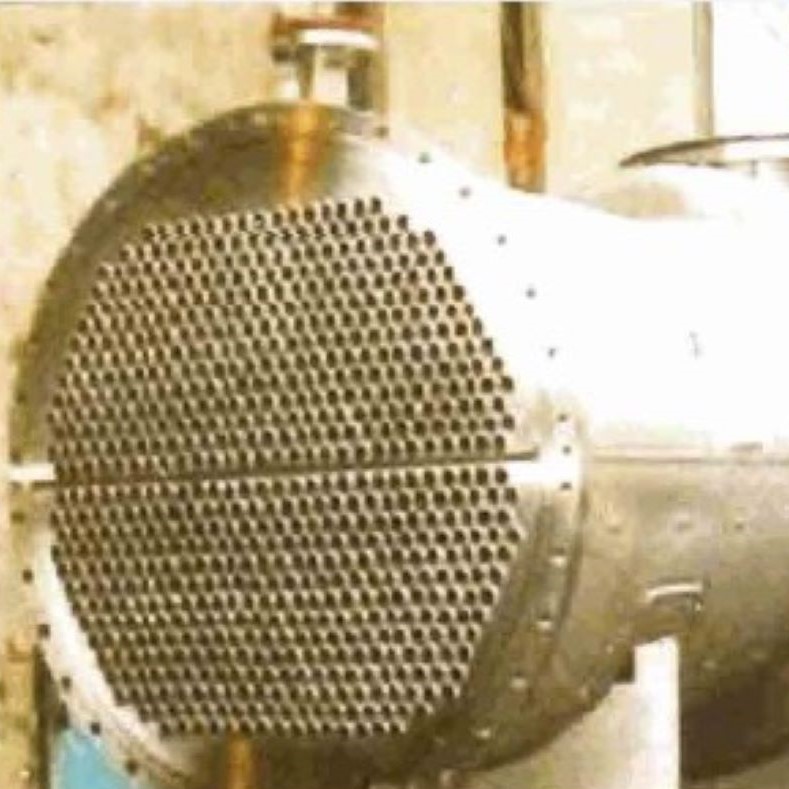

Azucar SS 309L is a universal electrode specifically designed for welding AISI309 type steels which are often used for furnace parts, heat exchanger and chemical processing equipment’s. This is also used for joining stainless steel to lower alloy steel and carbon steel. Good for building up of worn parts of wear resistant steel.

Before application the surface needs to be cleaned of fatigued deposits oil grease etc. The joints needs to be prepared. Porosity is more common in fillet welds then in butt welds were pores only occur at high moisture content.

Elongation on 4D: 35%

4.00mm X 350mm – 110 to 150 Amps

Polarity DC+AC 70 OCV min

Special SS Electrode

Azucar SS 310

CLASSIFICATIONS: AWS A5.4 E310-16 | ISO 3581 E25.20 R26 | DIN 8556 E25 20 R26

PACKING: 4.00mm X 350mm – 5 kgs plastic box

Azucar SS 310 is a all position rutile basic coated electrode of the 25% chromium and 20% nickel type. It is good for welding heat resistant AISI 310 grade materials and resists scaling in oxidizing atmospheres at temperatures up to 1100° C while maintaining adequate joint strength.

This is good in welding 25/20 stainless steel and welding of unknown steel to stainless steel. This is good for high temperature applications like heat exchangers, heat treatment trays and boxes, vats, tanks etc. This has low spatter loss with high strength and elongation properties.

Before application the surface needs to be cleaned of fatigued deposits oil grease etc. The joints needs to be prepared.

Tensile Strength (Mpa) => 580 (=58 kg/mm)

Elongation on 4D :> 37%

4.00mm X 350mm – 120 to 140Amps

Polarity DC +AC 70 OCV min

Special SS Electrode

Azucar SS 308L

CLASSIFICATIONS: AWS A5.4 E308L-16 | ISO 3581 E19.9L R26 | DIN 8586 E19.9 ncr 26

PACKING: 4.00mm X 350mm – 5 kgs plastic box

Azucar SS 308L is a rutile basic coated low carbon grade electrode for high quality welding of stainless steel of the 19% chromium and 9% nickel type. It is good for welding AISI 302, 304, 308 and 347 stainless steel.

With its high resistance to corrosion it is good for welding brewing equipment, steam piping, vacuum pump parts and dairy and distillery equipment. This is also used as a protective overlay on steel where complete corrosion resistance property is required.

Before application the surface needs to be cleaned of fatigued deposits oil grease etc. The joints needs to be prepared.

Tensile Strength (Mpa) => 570 (=57 kg/mm).

Elongation on 4D :> 43%

4.00mm X 350mm – 120 to 140Amps

Polarity DC +AC 70 OCV min

Special SS Electrodes

Azucar STS 312

CLASSIFICATIONS: AWS A5.4 E312-16 | ISO 3581 E29.9 R26

PACKING: 4.00mm X 450mm – 5kgs sealed packing.

This is a rutile basic coated electrode used for SS and welding repairs of any type of alloy steel components like shafts, impellers and heat resistant steel. This has 30% Cr and 10% nickel and extra low carbon variety with carbon content of only 0.03%. This has got more than 40% ferrite structure and successfully welds any unknown compositions. The structure is highly resistant to hot cracking and extremely tolerant of dilution from medium and high carbon steel.

Azucar STS 312 is a universal electrode specifically designed for welding steels of low weld ability. This is suitable for welding austenitic manganese steel, medium and high carbon hardenable steels which may be of unknown composition. This is also used for crack sensitive joints, built up of shafts or for repair of load bearing areas like sugar roller journal.

Before application the surface needs to be cleaned of fatigued deposits oil grease etc. The joints needs to be prepared and in some cases a preheat of 200°C is recommended for certain high alloy steel. Porosity is more common in fillet welds than in butt welds where pores only occur at high moisture content.

550 to 650 Mpa (115000 psi).

Elongation: 24%

4.00mm X 350mm – 110 to 150Amps

Polarity DC +AC 70 OCV min

Cast Iron Electrodes

Azucar STS CiFeNi

CLASSIFICATIONS: AWS A5.15 ENIFe-Cl

This is a ferronickel cast iron electrode i.e CiFeNi. The weld deposit of this electrode gives 50 to 55% Nickel and balance Iron (Fe). This produces machinable welds in cast iron without any preheat. This can be used for dissimilar joints such as cast iron to carbon, steel and nickel based alloys.

This electrode has been specially designed for the rectification and repair of all commercial grade of cast iron where machining after welding is to be carried out. Preheating and post weld heat treatment is not required in many applications where the location of the defect or shape of design is such that high stresses are not developed.

When welding without preheat it is essential to restrict the heat input by using the smallest possible diameter electrode and lowest possible current to limit the width of the heat effected zone. No continuous welding to be done but a scattered or planned wandering system has to be followed. When welding thick sections preheat to 300° C (approx..) and allow to cool slowly after welding.

Tensile Strength 55000 psi.

Elongation: 10%

4.00mm X 350mm-90 to 135Amps

Polarity DC +AC 70 OCV min

Cast Iron Electrodes

Azucar CiNi

CLASSIFICATIONS: AWS/SFA E Ni – Ci

PACKING: 1kg/pkt x 12 pkt – 12kgs sealed packing

Azucar CiNi is a medium coated pure Ni wire for specially designed for welding for known and unknown cast iron base metal. The Ni deposit does not pick up Carbon from base metal.

Azucar CiNi is used for welding of all types of cast irons (known and unknown Ci), cast iron to mild steels joining. Rectification of defective castings.

Use short arc and stringer bead not longer than 70mm peen each bead and remove slag thoroughly for stress relieve ensure the welding not to hot the base metal.

2.5mm x 350mm – 50-70 Amps

3.15mm x 350mm – 70-100 Amps

4.00 mm x 350 mm – 100-120 Amps

5mm x 350mm – 140-150 Amps

Polarity AC 70V/DC(+) min

General Purpose Electrodes

Garuda E6013

CLASSIFICATIONS: IS 814 ER 4224X | AWS A5.1 E-6013

Garuda E6013 is an all-position medium coated mild steel electrode of outstanding quality permitting use of Low open circuit voltage, excellent welding performance and mechanical properties with Radiographic Soundness are easily achievable

Garuda E6013 is suitable for all types of mild steel structural, plant machinery pipes and dredgers.

Tensile Strength (N/mm2) – 410 – 510

Yield Strength (N/mm2) – 330 Min

Elongation (L-5d) % – 22 min

CVN IMPACT@0°C – 47 J min

2.00mm – 40-60 Amps

2.50mm – 60-90 Amps

3.15mm – 100-140 Amps

4.00mm – 140-190 Amps

5.00mm 180-240 Amps

General Purpose Electrodes

Garuda 7018LH

CLASSIFICATIONS: IS 814 EB5426H3JX | AWS A5.1 E-7018

Garuda E-7018 LH is a basic coated iron powder electrode with hydrogen control electrode. The Arc is stable quiet and smooth. Self-disposing slag and superb welding performance. Weld metal is of Radiographic quality. High notch ductility at sub-zero temperature and weld metal recovery is 115% (approx.) multi positional electrode.

Welding of mild steel, pressure vessel, ship plates boilers, penstocks and all jobs involving static and dynamic loading. Also welding of heavy sections, free cutting steels etc.

Tensile Strength (N/mm2) – 510 – 650

Yield Strength (N/mm2) – 360 Min

Elongation % – 24 min CVN IMPACT@30°C -47 J min

2.50mm – 60-100 Amps

3.15mm – 100-140 Amps

4.00mm 140-190 Amps

5.00mm – 190-240 Amps

6.30mm – 240-300 Amps

COMPARISON CHART

Between Brazil Azucar100 and Chromcarb N6006

Specifications | Azucar 100 Hard Facing Electrode – (Brazil Make) 4mm and 3.25mm | Chromcarb N 6006 |

Weld Metal Composition | C – 4.10 to 4.5% Si – 3 to 3.52% B – 0.35 to 0.50% Mn – 0.60 to 0.75% Cr – 35 to 37% S&P – 0.050 max Hardness 58 to 62 HRC EN-8 and EN-9 steel | C – 3.5% max Si – 1.25 to 1.75% B – 0.35 to 0.50% Mn – 0.50 to 0.75% Cr – 29 to 31% S&P – 0.050 max Hardness 58 to 62 HRC |

Core Wire Diameter and Composition | 4mm and 3.25mm electrode quality MS. Current Carrying Capacity 140 to 200 Amps for 4mm and 90 to 140 Amps for 3.25mm | 4mm stainless steel wire Current Carrying Capacity 120 to 160 Amps |

Flux Coating Diameter | 8.15mm and 6.25mm (Rutile base with alloying elements) | 6.5 to 7.00mm (Rutile base, most of the alloying material comes from the core wire) |

Application | ID fan blade, TRPF roller, anvil plates, trash plate, and hammers. Also, both cast iron and steel mechanical grabs. | ID fan blade, TRPF roller, anvil plates, trash plate, and hammers. Also, both cast iron and steel mechanical grabs. |

Performance Credibility | The deposits of Azucar-100 give excellent results with service conditions of severe abrasion and moderate impact and friction. Retains hardness at a maximum temperature of 620°C. In most hardfacing applications, 90% of the service life compared to 6006 is guaranteed. Success rate is 95%. | Excellent in application under severe abrasion impact. Friction can retain hardness at a high temperature of 730°C. The stainless steel core wire gives weld deposits that can withstand severe impact. Success rate is 98%. |

Deposition Rate | 85 to 92% recovery with low spatter loss | 72 to 85% recovery with low spatter loss |

Market Price | Azucar 100 is 35 to 40% cheaper than L&T 6006 | Nearly twice as expensive compared to Azucar 100 |